Safety Job Analysis is the integration of accepted health and safety principles and practices for a particular job or task. In this blog, we will refer to this procedure as a “ Job Safety Analysis” (JSA), job safety analysis OSHA or safety job analysis. The purpose of the safety job analysis is to identify potential hazards and mitigate exposure through control methods that establish the safest way to perform a job task.

The result of a safety job analysis is an easy-to-understand document that can be shared with workers as part of pre-job and safety meetings, and/or as part of workers’ job descriptions. The safety job analysis process can be used to help refine safe work procedures outlined in safety manuals or standard operating procedures, and the joint assessment document can serve as a useful tool in training new employees.Workers and management must understand safety job analysis to make the job safer. Instead, workers and management must understand the risks and hazards associated with the job and know how to use selected controls in a way that eliminates or mitigates those risks. The safety job analysis documents the decisions of this process.

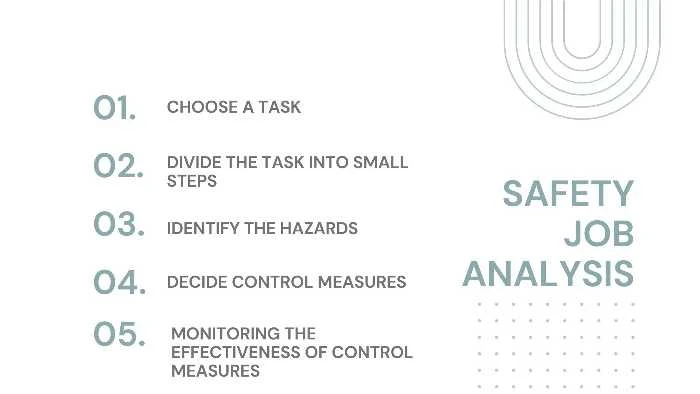

What are the 5 steps of safety job analysis?

Effective risk management begins with identifying and addressing hazards before incidents occur. The challenges of conducting a safety job analysis often prevent companies from completing them. Without a solid understanding of the hazards and risks, your employees face with the tasks they perform daily, staying consistent with safety is difficult.

Job safety analysis is a systematic technique used to analyze the potential risks associated with specific processes and procedures for a given job. The safety job analysis process generally consists of five steps:

- Choosing the appropriate job to analyze: Identify and document all tasks or categories of work that will be included in the process.

- Breaking down work into smaller tasks: and observing how it is performed by one worker: list each step of the process in sequence. For example, if you chose ‘scaffolding erection, modification and dismantle’ your steps should be (a) Preparation of work such as authorization, tools PPEs inspection etc. (b) Scaffolding components loading from laydown (c) Mobilization materials and manpower to the site (d) Manual off-loading material at the site (d) Erection, modification or dismantle of scaffolding (e) Housekeeping (f) Demobilization of materials and manpower.

- Identify possible hazards and risks in each task: Identify and document the hazards associated with each task or category of tasks. Consider all kinds of potential risks: physical, chemical and environmental. An example of this is commercial agents who, during their office work, are not in great danger, but when visiting a client outside the organization’s facilities, they may be affected by crime or traffic accidents.

- Establish preventive measures and controls to prevent identified hazards: Considering the hierarchy of controls (see below), identify and document the controls that must be used to control any identified hazards.

- Monitoring the effectiveness of control measures: It is necessary to record the process, to subsequently measure the efficiency of the implemented measure and its effect on the reduction or elimination of some risks. If you fail review it.

- Continuous monitoring and analysis of work

- Discovery of new potential workplace hazards and hidden unsafe conditions

- Review of inadequate procedures and malpractice at work

- Improves the relationship between supervisor and worker

- Identification of training opportunities and

Note: List all the people who contributed to the safety job analysis. The safety job analysis process should be a collaborative effort between the supervisor or principal investigator and the staff who will perform the identified task(s).

Hazard prevention program hierarchy of control

The hierarchy of control creates a systematic approach to managing workplace safety by providing a structure for selecting the most effective control measures to eliminate or reduce the risk of certain hazards arising from the work. The control hierarchy has six control measures, with the most effective at the top of the hierarchy and the least effective at the bottom. You should always start at the top of the chart and work your way down. The hierarchy of control includes the following important steps:

- Elimination – removes the cause of danger completely (e.g., the performance of a hazardous job in a non-hazardous way). This may include the use of a fixed ladder system in good condition to access a roof instead of an extension ladder.

- Substitution – controls the hazard by replacing it with a less risky way to achieve the same outcome (e.g., replacing a harsh solvent chemical for cleaning equipment with a non-hazardous cleaner).

- Isolation – separates the hazard from the people at risk by isolating it (eg, lock-out/tag-out procedures that de-energize a piece of equipment).

- Engineering – using engineering controls (ie, making physical changes, to lessen any remaining risk – e.g., redesign a machine by adding safeguards or introducing machinery that removes the hazard

- Administration – use administrative controls to lessen the risk (eg, install signs or rotate jobs).

- Personal Protective Equipment (PPE) – require your employees to wear PPE (e.g., provide gloves, earplugs, goggles, respirators, vests, steel toe shoes and ensure employees are trained in the use.

Why is job safety analysis important?

When you work at a construction site, you have a goal to return home safely. While some dangers are already visible and easily noticed, others are hidden. But how do you confirm to ensure safe workplace conditions or safe job performance at the construction site?

You may have heard it called a Job Safety Analysis (JSA), safety job analysis, Job Hazard Analysis (JSA) Safety Task Analysis (STA) or any other name. No matter what terminology is used, it all is the same. The JSA process is documented and used in the workplace or on the job site to guide workers in safe job performance.

A safe and healthy workplace not only protects the worker from injury and illness, but can also reduce injury/illness costs, reduce absenteeism and turnover, increase productivity and quality, and increase employee morale.

For insurance, a professional’s assignment often involves inspecting a workplace that has experienced hazards, which carry potential risks to people, plants and the environment. By performing a routine safety job analysis before working on each project safety is enhanced while meeting federal worker protection standards.

How do you do a job safety analysis?

An occupational hazard analysis is detective work. Your goal will be to discover the following:

What can go wrong? For example, you will need to be concerned about issues such as asbestos, lead-based paint etc. Based on job observation, knowledge of the causes of accidents or injuries, legislation and personal experience, list the things that could go wrong at each step.

What are the consequences? Falling from a ladder can have serious consequences. By using the proper ladder, checking for defects, placing it level on a solid surface, and applying the “three point of contact” rule, you can better mitigate the consequences of a fall.

Long-term asbestos exposure and lead-based paint can have long-term consequences. Following proper protocols during a renovation or repair, when materials known to contain or may contain these hazards are disturbed, reduces the risk of future health impacts.

How likely is the hazard to occur? Experience is crucial to fully evaluate this question. Ask another expert for help if you come across something new that poses a potential health or safety threat.

Methods used to make a safety job analysis

The employer must verify that the written safety job analysis that has been carried out in the workplace identifies the workplace hazards, evaluates the risk and decides on control measures.

The circumstances and environment of the project works are constantly changing. When any aspect of the job changes concerning new materials, new equipment, new methods, or new environments, a new safety job analysis must be performed.

- Observation method: Observation is key to establishing the stages and determining the potential risks associated with each of them. To carry it out, the observer must check several times before completing the identification and it must be done with different workers when carrying out work.

- Discussion method: It requires the involvement of both the supervisor and the most experienced workers so that they can discuss the primary stages and risks associated with each of them.

- Remember and check the method: The supervisor carries out the act based on her experience, once it is done, the verification is carried out under observation and discussion with the workers and other company supervisors.

- Questions answers method: To make your job hazard analysis useful, document the answers to these questions systematically. Describing a hazard in this way ensures that your efforts to eliminate the hazard and implement controls are identifying the major contributing factors to the problem at hand. To identify potential risks, consider questions such as the following:

- Can any part of the body get trapped inside or between objects?

- Do the tools, machines or equipment present risks?

- Can the worker have harmful contact with moving objects?

- Can the worker slip, trip or fall?

- Can the worker get a sprain from lifting, pushing or pulling objects?

- Is the worker exposed to extreme cold or heat?

- Is excessive noise or vibration a problem?

- Is there any danger due to falling objects?

- Is lighting a problem?

- Can weather conditions affect safety?

- Is harmful radiation a possibility? (Including sun exposure)

- Can there be contact with hot, toxic or caustic products?

- Are there dust, gases, mist or vapours in the air?

- Is there a possibility that the asbestos will be altered?

- Are there other contractors on the job doing unsafe acts?

Job safety analysis template download

The Job Safety Analysis (JSA) template, safety job analysis or Job Hazard Analysis (JHA) template is a useful tool for looking at and breaking down high-risk tasks into individual subtasks to suggest corrective actions. Supervisors and employees can use these templates together to ensure they both have a good understanding of how to address identified hazards and risks.

The safe work analysis (JSA) must be carried out in activities or tasks that the environment, the processes and facilities of the company, mainly all those activities that do not have a procedure, in addition to the activities considered of higher risk potential due to its accident statistics:

- Works with energy (electric, pneumatic, mechanical).

- Work at heights.

- Work in confined spaces.

- Hot work.

- Jobs involve chemicals etc.

It is essential to establish the methodology that will be used for the continuous identification of hazards and evaluation of the risks in industrial safety and occupational health associated with the processes, operations, activities and services in the workplace, to prioritize and determine the order prevention, protection and control measures.

The risk analysis for hazard identification and risk control must include the determination of the magnitude of the risk (MR) and the necessary controls for its prevention, protection and control.

The magnitude of the risk (MR) must be obtained by associating the probability of occurrence of the risk (P), with the exposure of the workers (E) and the severity of the damage (S) that it can cause, applying the following equation:

MR = P * E * S

Where: MR = magnitude of risk;

P = probability of risk occurrence;

E = worker exposure to risk;

S = severity of the damage.

You can Formal JSA Download a complete sample of safety job analysis and customize it for your workplace.

Is JSA and risk assessment the same?

JSAs and risk assessments are often confused or used synonymously, but there is a tangible difference between a JSA and risk assessment that makes it important to differentiate our scope. Two steps are used in both whether JSA or RA:

- Identify existing or potential hazards at each stage;

- Determine control measures to prevent risks.

Both are carried out by the work team of the area before carrying them, focusing on detecting all the dangers and risks to which they will be exposed to be able to control and mitigate them, and also to ensure that there is everything necessary for the personnel to have available (materials, tools, equipment, machinery, etc.) before carrying out the work.

The main difference between a safety job analysis and a risk assessment is the scope. A safety job analysis involves specific job hazards and typically focuses on the risks associated with each step of that task. Job Safety Analysis (JSA) is the process of analyzing, planning, and documenting in writing, in a detailed, complete, and thorough manner, the step-by-step sequence of a specific job.

The process typically involves breaking the job down into a series of steps and then understanding and controlling the hazards associated with each step and monitoring the effectiveness of control measures. A risk assessment provides a higher level or broader view of all operational risks across the business, project or type of activity.

A risk assessment is a formal safety process that identifies all the risks associated with an activity or operation. Once identified, each risk is analyzed along a couple of critical dimensions and controls are then put in place to mitigate or eliminate as many risks as possible, using the analysis to prioritize certain risks.

Job hazard analysis checklist template

Conducting safety job analysis can be challenging, but with proper guidance and communication with employees, jobs can be easily broken down into specific tasks for hazard identification and risk control application. This is an example of occupational risk analysis:

Job Title: Welder

Analyst: The Safety Zone

Date: July 17, 2022

Description: The worker is performing welds for the stair railing.

Hazard type: Physical hazard

Description: Electric arc can cause serious eye damage which can lead to employee blindness

Consequence: Major injury

Hazard controls:

- Welding operators must be trained or certified.

- Make sure all welding cables, wires and electrode holder insulation are in good working order.

- Make sure the work area is well-ventilated.

- Use the appropriate PPE.

- The arc shield should provide an additional layer of protection.

Safety Job Analysis checklist download

Job safety analysis examples pdf

Conclusion

Remember that not all hazards are immediately apparent and may not be detected by sight or smell alone. Job Safety Analysis is not a foreseen tool, but is an integral step in the evaluation process and must be executed properly. Asking the right questions, considering all possible outcomes, following the necessary safety protocols during each job inspection and ensuring compliance can reduce the risk, allowing the job to be evaluated effectively.